What is CUES?

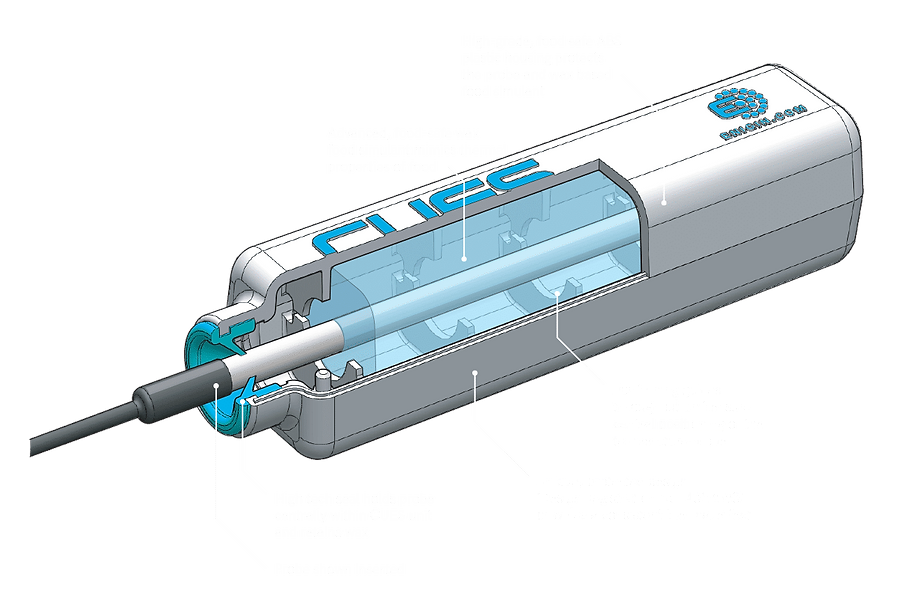

CUES stands for “Chilled Unit Energy Saver”. It is a retrofit device that can fit on any cooling unit inside a with a standard air sensing probe, to more accurately mimic the temperature of its contents.

The thermodynamics of food and beverages vary significantly from that of air. A standard thermostat probe inside a cooling unit measures the air temperature. If someone opens a door and warm air rushes in, the compressor will kick on right away to cool the unit even though the temperature of the food and beverages has not changed at all. Because of this discrepancy, the compressor runs more frequently than is necessary, leading to both increased energy usage and unnecessary wear and tear on the compressor unit.

How does the CUES work?

The CUES unit can be easily installed on the probes of your existing thermostat. Once installed, the thermostat probes measure the temperature through the CUES system, mimicking the internal temperature of food. When it starts to change in temperature, the compressor will kick on to maintain the desired temperature. This happens much more slowly than it would if the probes were measuring air temperature, resulting in fewer compressor cycles, lower energy consumption and extended life of the cooling unit.

Why Choose CUES?

Energy Savings, Guaranteed:

CUES optimizes cooling system operation, minimizing energy wastage. By maintaining consistent temperatures and preventing unnecessary fluctuations, it ensures efficient performance. CUES Energy Savers can help you save up to 33% on energy costs.

Less Wear and Tear: CUES prevents frequent cycling of the compressor, reducing wear and tear on the cooling system. Compressors that run efficiently last longer. CUES Energy Savers can help you extend the lifespan of your Compressor up to 80%.

Reduced Carbon Footprint: By consuming less energy, CUES directly contributes to environmental conservation. The Environmental Protection Agency (EPA) estimates that every kilowatt-hour saved prevents approximately 1.5 pounds of CO₂ emissions.

The CUES Energy Saver is independently-certified for NSF-approval, easy to install and has a very fast ROI.

Case Studies

The CUES unit can be easily installed on the probes of your existing thermostat. Once installed, the thermostat probes measure the temperature through the CUES system, mimicking the internal temperature of food. When it starts to change in temperature, the compressor will kick on to maintain the desired temperature. This happens much more slowly than it would if the probes were measuring air temperature, resulting in fewer compressor cycles, lower energy consumption and extended life of the cooling unit.

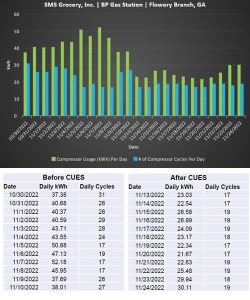

Brief Overview – BP is an oil and gas “supermajor” with more than 6,900 stores in the United States. They have an outlined plan for transitioning to a lower-carbon footprint and they advocate for policies aimed at achieving Net Zero by 2050. As such, a busy store in Flowery Branch, GA agreed to trial CUES* in their walk-in cooler – reducing its energy usage by 42%.

Project – A 12-day initial data monitoring period WITHOUT CUES* yielded that the compressor used 518kWh of energy and cycled 287 times. Following this initial survey, CUES* was installed, the system was cleaned and brought back to full freon capacity, and temperature was adjusted to achieve the desired range. Over the same time period WITH CUES* the compressor used 298kWh of energy and cycled 218 times. This demonstrated an energy reduction of 220kWh or 42%.

Compressor Life – The national average price of a new compressor with refrigerant and install is $9,000 with an expected lifespan of 10 years. A 74% increased lifespan on a brand new unit would represent a lifespan increase of 7.4 years and a savings of $6,660 each.

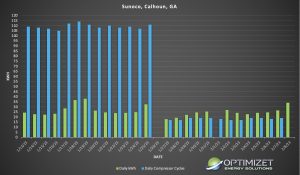

Project – Initial data monitoring period WITHOUT CUES* yielded that the compressors used339 kWh of energy and cycled 793 times. Following this initial survey, CUES* was installed and temperature was adjusted to

achieve the desired range. Over the same time period WITH CUES* the compressors used 283.01 kWh of energy and cycled 245 times. This

demonstrated a compressors cycle reduction of 74% / 43% / 74% and an

energy reduction of 16%.

Final savings amount – Predicted Lifetime Value: $29,602

Compressor Life – The national average price of a new compressor with refrigerant and install is $9,000 with an expected lifespan of 10 years. A

65% increased lifespan on a brand new unit would represent a lifespan increase of 6.4 years and a savings of $5,760.

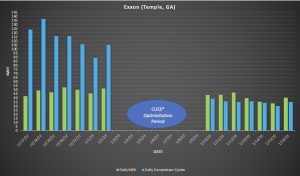

Project – Initial data monitoring period WITHOUT CUES* yielded that the compressor used 480.85 kWh of energy and cycled 434 times. Following this initial survey, CUES* was installed and temperatures were adjusted to achieve the desired range. Over the same time period WITH CUES* the compressor used 193.31 kWh of energy and cycled 148 times. This demonstrated a compressor cycle reduction of 64% and an energy reduction of 26%.

Final savings amount – Predicted Lifetime Value: $7,743

Compressor Life – The national average price of a new compressor with refrigerant and install is $9,000 with an expected lifespan of 10 years. A 71% increased lifespan on a brand new unit would represent a lifespan increase of 7.1 years and a savings of $6,390.

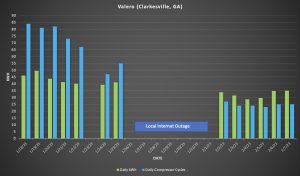

Project – Initial data monitoring period WITHOUT CUES* yielded that the compressor used 138.18 kWh of energy and cycled 558 times. Following this initial survey, CUES* was installed and temperature was adjusted to achieve the desired range. Over the same time period WITH CUES* the compressor used 53.98 kWh of energy and cycled 168 times. This demonstrated a compressor cycle reduction of 71% and an energy reduction of 61%.

Final savings amount – Predicted Lifetime Value: $7,567

Compressor Life – The national average price of a new compressor with refrigerant and install is $9,000 with an expected lifespan of 10 years. A 71% increased lifespan on a brand new unit would represent a lifespan increase of 7.1 years and a savings of $6,390 each.

Project – Initial data monitoring period WITHOUT CUES* yielded that the compressors used 352 kWh of energy and cycled 1,419 times. Following this initial survey, CUES* was installed and meters were adjusted to achieve the desired temperature. Over the same time period WITH CUES* the compressors used 292 kWh of energy and cycled 359 times. This demonstrated a compressors cycle reduction of 71% for each compressor and a total energy reduction of 15%.

Final savings amount – Predicted Lifetime Value: $10,428

Compressor Life – The national average price of a new compressor with refrigerant and install is $9,000 with an expected lifespan of 10 years. A 65% increased lifespan on a brand new unit would represent a lifespan increase of 6.5 years and a savings of $5,850.

Project – Initial data monitoring period WITHOUT CUES* yielded that the compressors used 102.48 kWh of energy. Following this initial survey, CUES* was installed and temperatures were adjusted to achieve the desired. Over the same time period WITH CUES*… …the compressors used 66.43 kWh of energy. This demonstrated an energy reduction of 35% and achieved an overall compressors cycle reduction of 65%.

Final savings amount – Predicted Lifetime Value: $27,456

Join the Efficiency Revolution!

Upgrade your cooling system with CUES today and experience the perfect blend of efficiency, savings, and environmental responsibility. Your cooler deserves the smart choice—choose CUES!

One Comment